Professional Roofing Contractor in Indianapolis, IN

Is it time for roof replacement? In need of a quality and experienced roofing contractor? At WaterTight Roofing, we offer a wide range of outstanding roofing options across Indianapolis, IN that include Owens Corning, GAF, Certainteed and Malarkey .

Your Roofing Decisions

Typical roofing products include Asphalt Shingles and Metal Roofing. (most residential roof installations are asphalt shingles). Aesthetics and good value are the primary reasons for this selection. Most custom homes will feature higher end asphalt composition shingles, wood shingles or concrete tile.

Your Residential Roofing Contractors in Indianapolis, IN

Your roof should protect your home from the elements. If it’s not doing its job, you’ll end with damaged shingles and it’s time to seek professional help. WaterTight Roofing and Exteriors is a residential roofing installation and roof repair company in Indianapolis, providing honest, reliable roofing services to protect your home. You have many choices for roofing materials; our roofing contractors can help you choose the best solution to increase your property value, improve energy efficiency, and boost curb appeal, giving you peace of mind that you’ve invested in a long-lasting roof.

Expert Roof Installation

Whether you need a roof for new construction or your roof needs replacement, you can trust our residential roofing installation services in Indianapolis, IN, to provide quality services at reasonable rates. We work with many roofing materials, giving you dependable options that give you the desired aesthetics and energy efficiency. You can find options like Owens Corning, GAF, and Certain teed, allowing you to find the best solution for your home at competitive rates.

We’re Available for Roof Repairs

Our residential roofing contractors in Indianapolis, IN, are experts in roof repair. When you notice a problem, you can trust our team to inspect your roof and identify the issue. We arrive equipped to handle most roofing repairs on the spot, giving you confidence that your roof is restored. Our team aims to minimize long-term damage to protect your property and reduce costs. Our roof repair services come with a lifetime transferable warranty, giving you further peace of mind.

Ask The Important Questions

When interviewing prospective roofers to understand their actual knowledge of roof replacement,

Consider these top 10 ways you can determine for yourself if you are getting a quality roof.

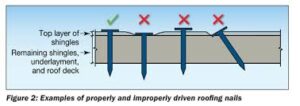

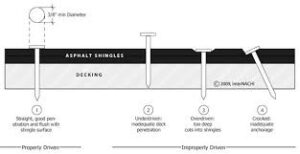

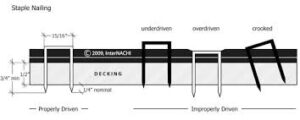

1: Nail placement; Absolutely the most overrated technique is to nail fast.

Fast nailing does not a quality roof make.

Improper nailing will puncture holes in the shingles and improper nailing such as crooked, overdriven or underdriven nails are why most warranties are null and void.

Fasteners MUST be placed into both layers of laminate shingles and unfortunately the manufacturing and packaging process is not user friendly and will most definitely cause leaks and blow offs in the very near future.

We believe having a much wider common bond area is a superior manufacturing technique which can only be found by a very few brands of shingles.

Version 1.0.0

The top 4 quality brands we use are Malarkey, Owens Corning, Gaf and Certainteed shingles.

WTR will be able to show you how these shingles are manufactured and how these differences can affect the water shedding capability of the shingles and its overall lifespan.

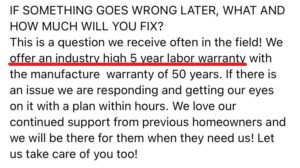

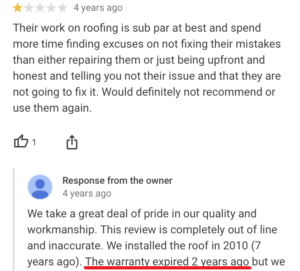

2: Warranty; Not the one from the manufacturer but, the labor and workmanship warranty from the installer/company. (Typically 2-5 years, sometimes 10?)

It is critical to understand that the warranty is for the contractor not for the homeowner. After the warranty expires the contractor has no obligation whatsoever to the homeowner and can legally just walk away leaving you with the headaches and charges you may incur due to faulty workmanship.

Many labor warranties are generally backed by the manufacturer after the first 5 years and may be limited to manufacturing defects and other exclusions such as prorated exclusions.

We found some interesting examples below.

WTR gives a limited lifetime “transferable” labor and workmanship warranty on all new products installed. All it takes is a warranty transfer form and we’ve done it many times.

3: Ice and water shield; Although not code in most Indiana counties, make sure you get it on gutter edges and valleys. WTR will install ice and water barrier to the eaves AND valleys of your home and by installing our “Patent Pending Watertight Method” to the overhangs of your home guarantee you will never have a rotten gutter board or soffit board.

The examples below show how the lack of ice and water shield will cause severe wood rot over time and plain organic felt paper is an out dated product that can also have many wrinkles and cause blemishes on the roof surface. This old style of organic felt paper actually was designed to soak up water that has either penetrated the shingles or has condensated under the shingles.

Sometimes we find other contractors installing felt paper over top of old paper which does not allow proper inspection of the deck surface below.

Always remove all roofing products down to the bare wood for proper inspection of the decking and prepping the surface prior to installing ice and water shield.

4: Ridge cap; “Cut down 3-tabs” are made with a thinner fiberglass mat than actual “Hip and Ridge accessory shingles” and have a high potential to blow offs because of the thinner fiberglass mat used during manufacturing.

These “Cut down 3-tabs” are typically used by most roofing contractors due to the cost savings as compared to “Hip and Ridge accessory shingles.

WTR will use actual “hip and ridge accessory shingles” that are thicker and also match the color of the laminate shingles much better than cut down 3-tabs and have the same wind rating as the laminate shingle that will be installed.

5: Ventilation; Proper ventilation is a much overlooked aspect to the quality, durability and longevity of any roofing system.

Sometimes turtle vents and ridge vents may be the #1 cause of roof leaks.

Unfortunately, your average roofer does NOT know how to properly install these type of vents and we can prove it.

Ridge vents MUST be “crowned” and when installing the ridge vent only one side at a time can be fastened as to prevent wrinkling of the ridge vent resulting in potential blow offs due to the extra stress on the ridge vent and buckling causing a wavy ridge due to improper fastening.

Turtle vents, a.k.a. Box vents or static vents MUST have shingles extending upward past the center of the hole it is covering. This will prevent water from draining sideways and getting under the shingles and leak through the felt paper. Fasteners go in the top and bottom never the edges where the water flows.

An easy rule of thumb is 2 shingles under and 2 shingles over.

WTR has properly trained crews that install products the same way every time. This ensures that small leaks due to improper installation will not show up 7-10 years later after your typical labor warranty has expired.

6: Pipe boots; It’s sad but most roofers still use plastic pipe jacks that have a 100% chance of getting rotten and causing a leak.

See the following examples of pipe boot failure.

WTR would prefer to use lead based pipe boots because lead does not rot and the lead flange encapsulates the soil pipe and leaks are nearly impossible. Unfortunately lead pipes are getting increasingly harder to find.

WTR may substitute lead pipe boots with polystyrene and add a “sleeve” over the main polystyrene pipe boot to prevent rot and therefore making the seal watertight for decades to come.

7: Low sloped roofs; Do NOT let anyone install shingles on low sloped roofs! No amount of ice and water shield will prevent low sloped shingled roofs from leaking.

If someone tells you any different, their labor warranty will prove how much confidence they have when installing shingles on pitched roofs lower than 4/12 pitch.

Shingles on low pitched roofs can not shed water. They will instead hold water as seen below.

Once the shingles are installed over the starter and first layer, the shingles are taller on the edge than on the shingles just above them and causes the shingles to curl backwards and hold water as seen below.

8: Chimney Flashing;

Every protrusion on your roof has a high risk of leaks. When installing chimney flashing it is vital that the flashing used will extend past each side of the back of the chimney and NOT cut back and folded around each end.

9: Plank Decking; Plank decking is NEVER a suitable nailing surface for asphalt shingles.

a: Proper nail placement is key to a properly fastened shingle roof and when those fastener areas line up where the planks are gapped or over a knot hole, the fastener will not hold due to being nailed into that gap or knot hole and will cause “nail blow through” and will cause a leak. Even if the fastener gets close to the gap the wood will split and will not properly hold the fastener.

b: On the under side of the deck these gaps and holes can be much worse. Unlike the butcher the worst side is always down when installing plank decking.

c: The larger the gap, the greater the possibility for the nails to line up in these gaps and they will cause leaks.

Even the insurance companies get more worried as the gaps get bigger. Although they may not want to acknowledge it.

d: Over time the plank decking dries out and starts to curl in the middle making the shingles also curl in the middle and hold more water.

e: Imperfections in the plank decking can cause dips and turns on the surface and water will penetrate and leak in.

The only safe procedure is to cover plank decking with plywood before installing shingles.

Shingles must have a smooth flat surface always sloping down in order for them to properly shed water from the roof.

No matter how large or small the gaps are both are considered spaced decking and must have plywood installed before applying asphalt shingles.

10: Felt paper; Outdated paper felt paper is actually designed to soak up moisture when your roof condensates moisture or when water gets forced under the shingles due to wind driven rain and ice dams.

Synthetic felt paper is designed to shed and block moisture that condensates under your shingles.

Most roofing companies use the new and improved synthetic felt paper however, you must demand that synthetic felt paper is being used to make sure your roof lasts the whole 30 years of its expected life.

At WaterTight Roofing, we have an exclusive “patent pending” application method when roofing your home and we are more affordable than the big guys!

We can’t do them all but, we can do them best.

“Quality unmatched until copied.”

“Better. Believe it.”

We have an exclusive “patent pending” application method when roofing your home and we are more affordable than the big guys!

Proposal

An itemized proposal with a list of existing problems that need correcting with the new roof should be the standard. Anyone can replace your roof however, who is going to provide a solution to fix all of your current issues you may have and correct those issues with a new roof?

Installation

Will the representative have extensive experience in replacing roofs or just selling roofs? Vents, pipe boots, ridge cap, nail placement and other critical items can NOT be overlooked when achieving a quality roof replacement. WaterTight Roofing and Exteriors has an exclusive “patent pending” application method which stops leaks caused by overflowing gutters and ice dams.

Materials

An itemized proposal with a list of existing problems that need correcting with the new roof should be the standard. Anyone in Indianapolis, IN can replace your roof however, who is going to provide a solution to fix all of your current issues you may have with a new roof?

Spaced sheathing

Proper Nail Placement is also critical to the warranty & performance of your new shingles. Manufacturers have very strict requirements for the placement of all fasteners through the shingles, & if not followed WILL void the warranty on the entire roof, even if only a few shingles are found to be improperly fastened.

Decking is the wood beneath your shingles. Manufacturers have requirements for this as well, for their warranties to apply. Decking must either be 4’x8′ sheets of plywood or OSB.

Older homes also may have 1×8, 1×10, or 1×12 boards that are NOT approved for shingle warranties. Excessive gaps or boards wider than 6″ require a minimum layer of 3/8” plywood or OSB to be installed over the old boards to achieve a solid, smooth, structurally sound deck for the application of felts, metal edgings, and shingles. Final decisions regarding decking costs can typically be made after careful inspection from the underside of the roof structure or when the old shingles are removed and a complete deck inspection can occur.

Sheathing over ship-lap decking, also shows the ridge opened up for ridge venting. Ship-lap, a type of plank decking installed from the 1930s into the 1960s has been known to cause issues with composition shingles due to its irregularities. The ship-lap, or any other “solid” plank type roof decking, were also typically green lumber (not kiln dried) and will shrink 5%-10% leaving gaps greater than ¼” and knotholes greater than 1”. When new it was actually a nice tight roof deck system. Over time the wood dries out, splits and cracks form, knots fall out and the boards warp and pull free from fasteners. It is common to see a bulge in roofs where the end of a plank has sprung from its anchoring and is now curling away from the roof. Because these boards continue to expand and contract with temperature & humidity the problems just keep getting worse as time goes along. Most composition shingle manufactures will not warranty their products when installed over old plank type roof decking.